What are Biodegradable Polymers? Market Insights, Synthetic Types & Real-World Examples

Introduction

If you’re a manufacturer, brand owner, packaging buyer, sustainability professional, policymaker, or eco-conscious business, this guide about Biodegradable polymers is written especially for you.

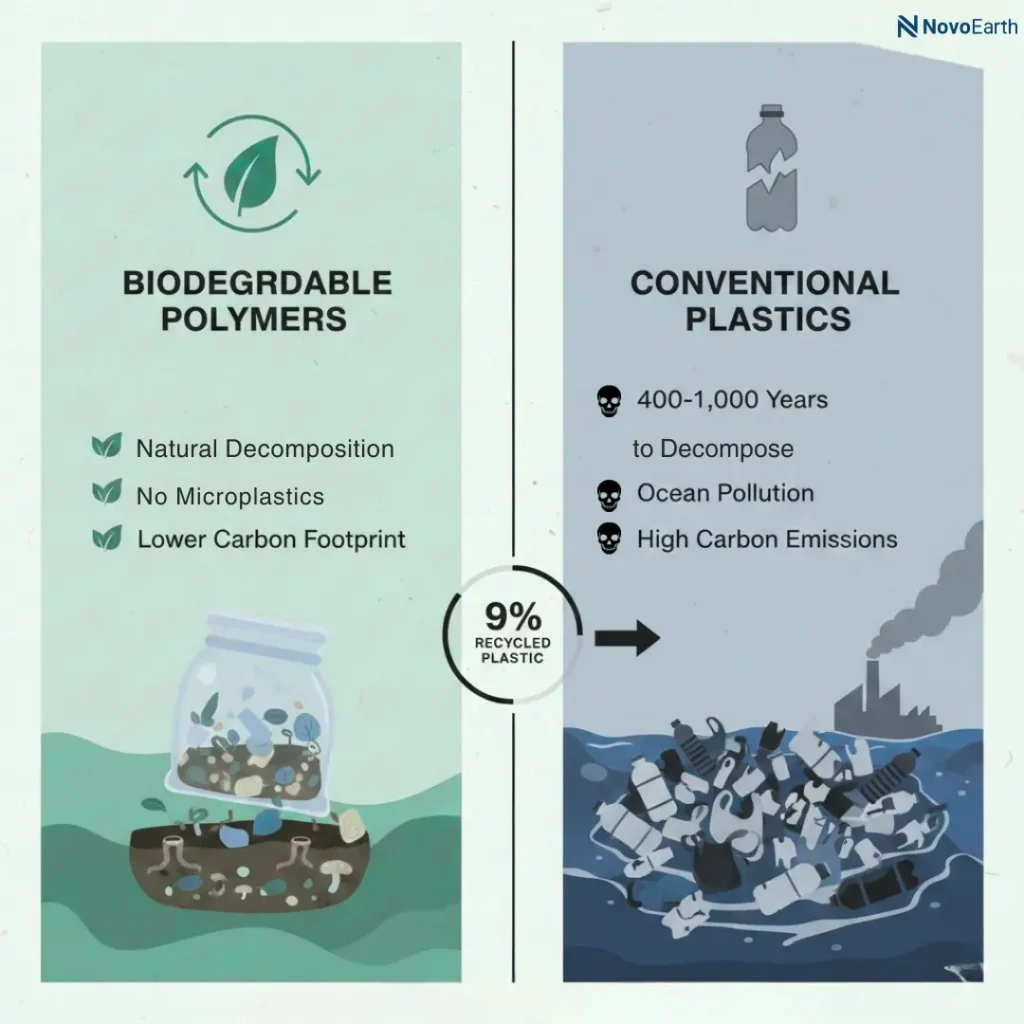

Traditional plastics take 400–1,000 years to decompose, clog landfills, pollute oceans, and increase carbon emissions. With plastic bans rising globally, businesses are struggling to find practical, scalable alternatives.

That’s where biodegradable polymers come in—materials designed to break down naturally, reduce environmental impact, and still perform like conventional plastics.

In this blog, we’ll break down:

- What biodegradable polymers are

- Synthetic biodegradable polymers explained simply

- Biodegradable polymers market size & trends

- Real-world examples you can relate to

What Are Biodegradable Polymers?

Biodegradable polymers are materials that decompose naturally through the action of microorganisms like bacteria and fungi into water, carbon dioxide, and biomass.

Unlike conventional plastics, biodegradable polymers:

- Do not leave microplastic residue

- Have a lower carbon footprint

- Support circular and sustainable economies

Fact: According to global waste studies, only 9% of plastic ever produced is recycled, while biodegradable polymers help reduce landfill dependency significantly.

Types of Biodegradable Polymers

Biodegradable polymers are broadly classified into natural and synthetic biodegradable polymers.

| Type | Source | Example |

| Natural | Plants & animals | Starch, cellulose, PHA |

| Synthetic | Chemically synthesized | PLA, PBAT , PBS |

What Are Synthetic Biodegradable Polymers?

Synthetic biodegradable polymers are man-made polymers engineered to decompose under specific environmental conditions, like composting or soil exposure.

They combine performance + sustainability, making them ideal for industrial use.

Common Synthetic Biodegradable Polymers

Polylactic Acid (PLA)

- Made from corn starch or sugarcane

- Widely used in packaging & disposable cutlery

- Compostable within 90–180 days under industrial composting

Polybutylene adipate terephthalate (PBAT)

- Despite being made from oil, its chemical structure is designed to be easily broken down by microbial enzymes.

- It is 100% biodegradable and compostable

Polybutylene Succinate (PBS)

- Heat-resistant and flexible

- Ideal for mulch films and food packaging

Performance Insight: Synthetic biodegradable polymers can reduce greenhouse gas emissions by 30–70% compared to petroleum-based plastics.

Biodegradable Polymers Market Size & Growth

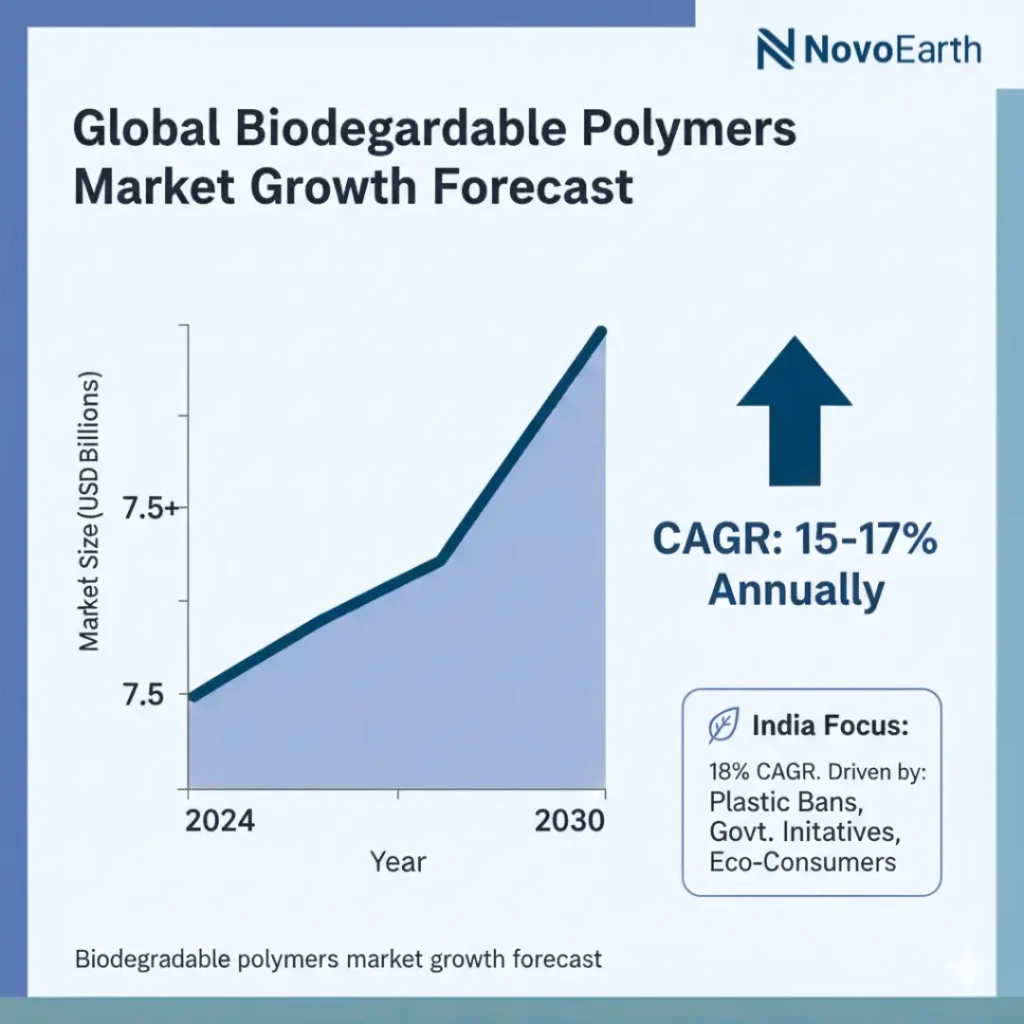

The biodegradable polymers market is growing rapidly due to sustainability regulations and consumer demand.

Market Snapshot

| Metric | Value |

| Global Market Size (2024) | USD 7.5 billion |

| Expected Market Size (2030) | USD 22+ billion |

| CAGR | 15–17% annually |

India Focus:

India’s biodegradable polymers market is expected to grow at 18% CAGR, driven by:

- Single-use plastic bans

- Government sustainability initiatives

- Rising eco-aware consumers

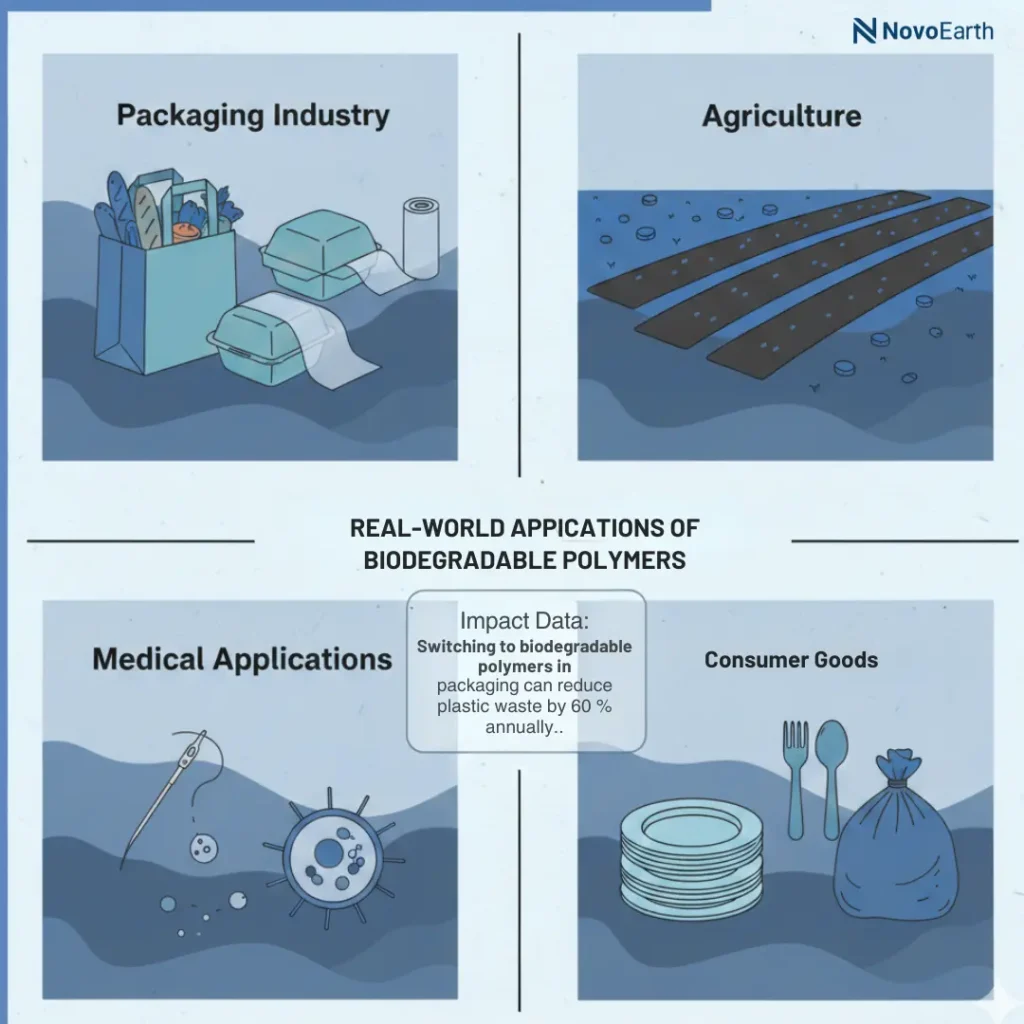

Real-World Examples of Biodegradable Polymers

Here’s how biodegradable polymers are already being used in everyday life:

Packaging Industry

- Compostable carry bags

- Food containers

- Flexible packaging films

Agriculture

- Biodegradable mulch films

- Controlled-release fertilizer coatings

Medical Applications

- Surgical sutures

- Drug delivery systems

- Tissue scaffolds

Consumer Goods

- Disposable cutlery

- Plates and cups

- Garbage liners

Impact Data: Switching to biodegradable polymers in packaging can reduce plastic waste by up to 60% annually for FMCG brands.

Alternate Section – Biodegradable vs Compostable Polymers

Many people confuse biodegradable polymers with compostable ones.

| Feature | Biodegradable Polymers | Compostable Polymers |

| Breakdown | Natural environments | Compost conditions |

| Timeframe | Variable | Fixed (90–180 days) |

| Certification | Optional | Mandatory |

Key Takeaway: All compostable polymers are biodegradable, but not all biodegradable polymers are compostable.

Why Businesses Are Switching to Biodegradable Polymers

- Compliance with plastic bans

- Improved brand reputation

- Reduced environmental footprint

- Future-ready sustainability strategy

Consumer Insight: 73% of consumers prefer brands using sustainable packaging.

FAQs on Biodegradable Polymers

Are biodegradable polymers completely eco-friendly?

Yes, when disposed of correctly, biodegradable polymers significantly reduce pollution and waste.

How long do biodegradable polymers take to degrade?

Depending on the material and conditions, 3 months to 2 years.

Are biodegradable polymers expensive?

Initially, yes, but costs are dropping by 10–15% annually due to scaling and innovation.

Can biodegradable polymers replace plastic entirely?

Not entirely yet, but they are ideal for packaging, agriculture, and disposables.

Why NovoEarth Is Leading the Change

At NovoEarth, we specialise in next-generation biodegradable polymers designed for real-world performance and sustainability.

What NovoEarth Offers:

- High-quality sustainable polymer solutions

- Custom formulations for packaging & industrial use

- Compliance with global sustainability standards

Ready to Switch to Biodegradable Polymers?

Partner with NovoEarth.co to future-proof your business with innovative biodegradable polymer solutions.

Visit: https://novoearth.co

Talk to our sustainability experts today

About the Author

Sarthak Gupta is a Mechanical Engineer and the founder of NovoEarth, a cleantech venture specialising in circular material innovation and sustainable polymer solutions. His expertise lies in biodegradable polymer technologies and recycling systems for multilayer plastics—complex waste streams traditionally considered non-recyclable. With prior experience in renewable energy and wind turbine design, Sarthak focuses on translating engineering innovation into scalable, commercially viable climate solutions.